所属分类:工程案例 > 流化床干燥工程案例 > 合成橡胶树脂干燥机

案例简介:Polyvinyl chloride (PVC) resin is one of the most widely used synthetic resins in the world, and its excellent physical and chemical properties have led to a wide range of applications in various fields, such as construction, electrical and electronic appliances, automobiles, and medical devices.

18651002062

18651002062 Polyvinyl chloride (PVC) resin is one of the most widely used synthetic resins in the world, and its excellent physical and chemical properties have led to a wide range of applications in various fields, such as construction, electrical and electronic appliances, automobiles, and medical devices. From a market perspective, the demand for PVC Resin is growing, especially in developing countries, where accelerated infrastructure development is driving PVC consumption. However, the limitations of the traditional drying process make the production enterprises urgently need to find more efficient and environmentally friendly drying solutions.

Traditional Dilemmas in Drying of Polyvinyl Chloride Resin

Drying is a crucial part in the production process of polyvinyl chloride resin. Traditional drying methods such as hot air drying and vacuum drying, although widely used, are faced with a number of dilemmas.

1. High energy consumption: traditional drying methods often require a large amount of thermal energy, resulting in higher production costs, especially in the context of rising energy prices, this problem is more and more obvious.

2. Uneven drying: the traditional drying equipment often appears the phenomenon of uneven drying of materials, resulting in unstable product quality, and even local overheating of materials, scorching and other problems, affecting the performance of the final product.

3. Long processing time: the traditional drying process usually requires a long processing time, which not only reduces the production efficiency, but also may lead to changes in the nature of the material, affecting the subsequent processing.

4. Environmental pollution: some traditional drying process may release harmful gases or waste heat, bringing pollution to the environment, especially in the increasingly stringent requirements of environmental protection, which is particularly important.

5. Complicated maintenance of equipment: traditional drying equipment often has complicated structure, high maintenance cost and high failure rate of equipment, which affects the continuity of production.

Aiming at the shortcomings of the traditional drying process, Jiangsu Bohong produces and manufactures the vibrating fluidized bed dryer, which realizes the efficient drying of PVC resin through the combination of vibration and airflow. Jiangsu Bohong vibration fluidized bed dryer with its unique working principle and technical advantages, is becoming an important equipment in the field of PVC resin production, for the realization of efficient, environmentally friendly production goals to provide strong support.

Ⅰ. Jiangsu Bohong Vibrating Fluidized Bed Dryer-Working Principle:

1. Fluidization principle: Vibrating fluidized bed dryer makes the material form a fluidized state in the bed through the airflow at the bottom. In this state, the contact between materials is more frequent, the exchange of heat and moisture is more efficient, and the drying speed is significantly improved.

2. Vibration: The mechanical vibration produced by the vibrator makes the materials turn over in the bed. This turning not only increases the surface area of the material and promotes the conduction of heat, but also avoids the bonding phenomenon of the material and ensures the uniformity of drying.

3. Airflow control: In the vibrating fluidized bed dryer, the drying process can be precisely controlled by adjusting the speed and temperature of the airflow to ensure that the PVC resin reaches the set moisture content. This flexible airflow control makes the whole drying process more efficient and controllable.

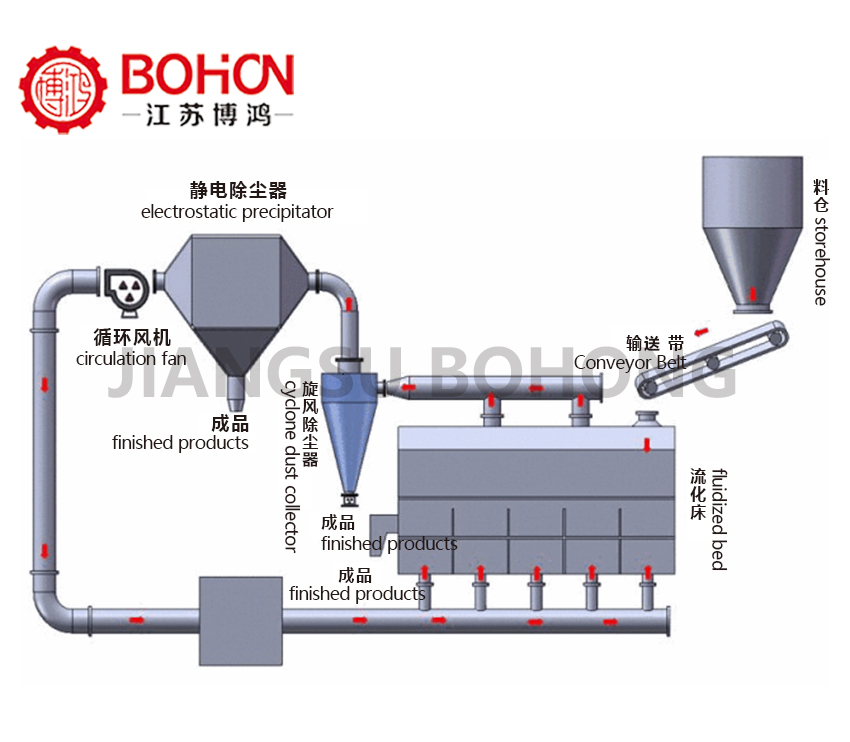

Ⅱ. Jiangsu Bohong Vibrating Fluidized Bed Dryer - Process Flow

The process of vibrating fluidized bed dryer is relatively simple and efficient, usually including the following steps:

1. Material pre-treatment: Preliminary screening of PVC resin to remove impurities and large materials to ensure that the materials entering the dryer are uniform.

2. Material placement: the pre-treated PVC resin is evenly placed into the vibrating fluidized bed.

3. Airflow heating: through the heating device at the bottom, the airflow is heated to the set temperature, and the airflow flows upward through the bed.

4. Vibration drying: After the equipment is started, the vibrator starts to work, and the vibration fluidizes the materials in the bed, while the hot airflow takes away the moisture in the materials.

5. Drying Monitoring: During the drying process, the status of the material is continuously monitored by the built-in humidity sensor and temperature sensor. The system will automatically adjust the temperature and flow rate of the airflow according to the monitored data to ensure that the material is dried under the best conditions.

6. Discharge and Cooling: After drying, the PVC resin is automatically discharged through the discharge port. During this process, the system is usually designed with a cooling device to prevent the material from deteriorating or binding due to high temperature during discharge.

7. Exhaust gas treatment: The vibrating fluidized bed dryer is usually equipped with an exhaust gas treatment device to ensure that the exhaust gas generated during the drying process is treated and then discharged, so as to reduce the impact on the environment and comply with the environmental standards.

Ⅲ. Jiangsu Bohong Vibrating Fluidized Bed Dryer-Technical Advantages

Jiangsu Bohong's vibrating fluidized bed dryer has a number of significant advantages in technology, specifically including:

1. Efficient drying: due to the use of fluidization technology, the material in the drying process can get more uniform heat distribution, drying speed significantly improved. Compared with the traditional drying equipment, it can reach the required moisture content in a shorter time.

2. Energy saving and environmental protection: the design of vibrating fluidized bed dryer makes it more optimized in energy utilization. Through precise control of airflow and vibration, it can effectively reduce energy consumption and carbon emission in the production process, which is in line with the sustainable development requirements of modern enterprises.

3. Drying uniformity: The combination of vibration and airflow makes the material maintain good fluidity during the drying process, avoiding the problem of uneven drying and ensuring stable quality of the final product.

4. Easy operation: the equipment has a high degree of automation, the operator only needs to set the relevant parameters, the system can automatically complete the drying process, and in case of abnormality, timely alarm, reducing the difficulty of operation and the risk of human error.

5. Strong adaptability: the vibrating fluidized bed dryer is suitable for many types of PVC resin, and can be adjusted according to different material characteristics and production requirements, with strong adaptability.

6. Small footprint: due to the compact design of the equipment, compared with the traditional drying equipment, the vibrating fluidized bed dryer requires a smaller footprint, which is suitable for production environments with limited space.

7. Low maintenance cost: the equipment has reasonable structure, low failure rate and relatively simple maintenance, which reduces the maintenance cost and downtime of the enterprise.

With the increasingly strict requirements for environmental protection and the continuous growth of the PVC resin market, Jiangsu Bohong's vibrating fluidized bed dryer has a broader application prospect in the industry. We will continue to optimize the drying process, so as to improve product quality and production efficiency to adapt to market changes.

上一篇:暂无产品

物料的含水量将直接影响电镀污泥干燥机的干燥效率和产品质量。含水率过高的物料在干燥过程中需要消耗更多的热能,干燥时间也较长,从而降低了设备的生产效率。

江苏博鸿干燥公司针对该物料特性专门设计一级采用空心桨叶干燥机,将物料内的水分从含水40%将至5%,然后直接由出料口将物料进入齿盘式高效粉碎机粉碎。

在污泥干化机中,滤板设置在污泥进料管的底部,当污泥通过污泥进料管时,污泥中的水在重力的作用下流入水池,减少了污泥中的水分,从而初步排水,节约了能源。

截屏,识别二维码

官网:

(点击复制官网简称)

截屏,识别二维码

微信公众号二维码:

(点击复制官网简称)

截屏,识别二维码

抖音企业号二维码:

(点击复制官网简称)

截屏,识别二维码

抖音喷雾产品号二维码:

(点击复制官网简称)