所属分类:流化床干燥

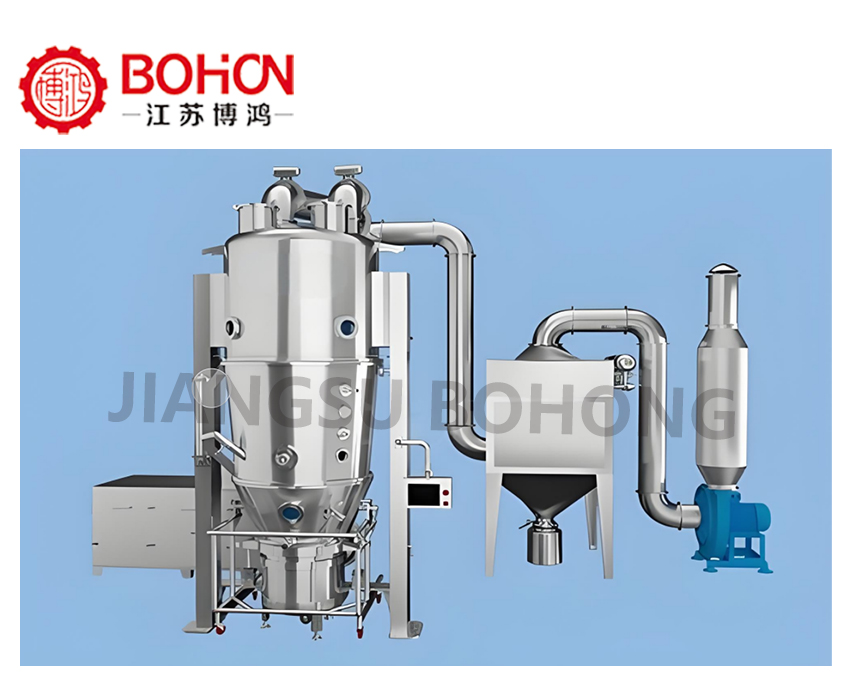

产品简介:The XLP series of rotary fluidized bed granulation dryers produced by Jiangsu Bohong Drying Equipment Co., Ltd. is an efficient material processing equipment that is widely used in the pharmaceutical, chemical, and food industries. The unique design and innovative airflow distribution system of the rotary fluidized bed granulation dryer enable it to exhibit outstanding performance in the processes of granulation and drying.

18651002062

18651002062 XLP series of rotary fluidized bed granulation dryers

The XLP series of rotary fluidized bed granulation dryers produced by Jiangsu Bohong Drying Equipment Co., Ltd. is an efficient material processing equipment that is widely used in the pharmaceutical, chemical, and food industries. The unique design and innovative airflow distribution system of the rotary fluidized bed granulation dryer enable it to exhibit outstanding performance in the processes of granulation and drying.

Jiangsu Bohong Drying provides a detailed introduction to the structure and working principle of the cyclone bed granulation drying equipment, and analyzes its impact on material movement, particle characteristics, and production efficiency.

1. XLP Series Cyclone Bed Granulator and Dryer - Special Design of Air Distribution Plate

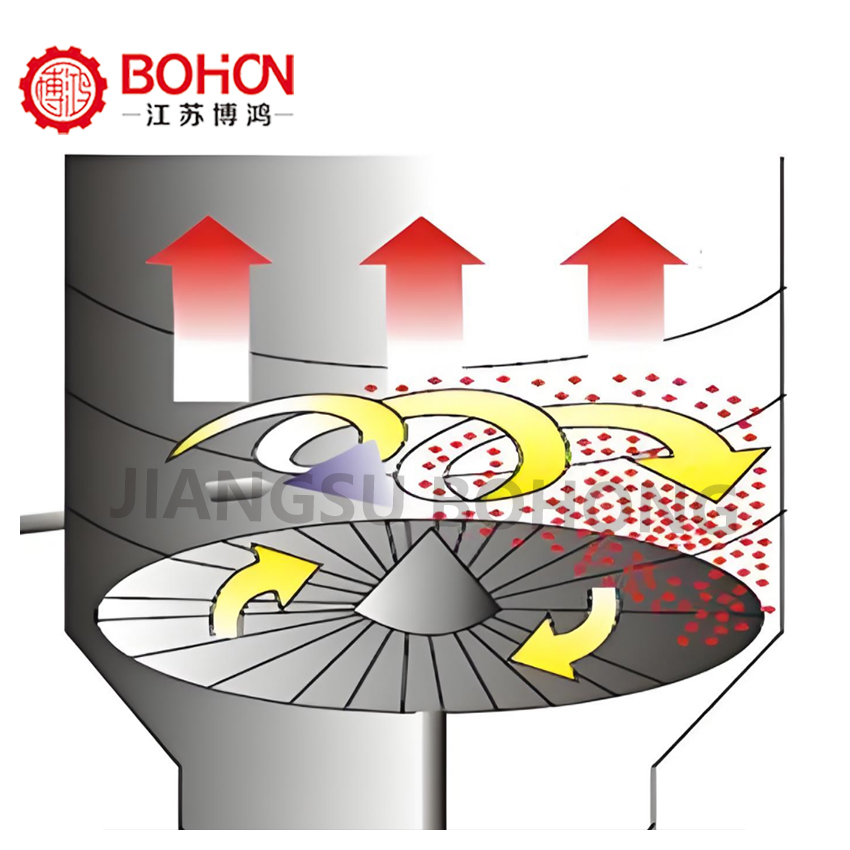

The core innovation of XLP series rotary bed granulator dryer produced by Jiangsu Bohong Drying Equipment Co., Ltd. lies in the design of its air distributor. Unlike traditional air distributors, the air distributor of XLP series equipment adopts a special ring-shaped plate structure. Each air distributor plate is arranged in a layered fashion, not only saving space but also optimizing the distribution of airflow. Airflow passes through the gaps between the plates to form a ring-shaped high-speed airflow. The high-speed airflow serves to push the material to perform orderly vortex-like movement within the drying chamber.

Vortex motion has two notable advantages over traditional linear flow. Firstly, material will not experience channelling, which is a phenomenon where certain areas of the material become stagnant or experience uneven airflow, leading to uneven drying or granulation. Channelling occurs when material flow is impeded or airflow is uneven, causing certain areas of the material to not move effectively, resulting in uneven drying or granulation. Secondly, vortex motion avoids the formation of dead zones within the equipment, ensuring that all material is evenly involved in the granulation and drying process. This has important implications for the uniformity of the material, the size and shape of the particles.

2. XLP Series Cyclone Bed Granulator and Dryer - Air Distribution System with Cyclone-Driven Air Distribution

Jiangsu Bohong Drying Co., Ltd. ensures that the material remains in an orderly motion during the drying process by equipping the XLP series of fluidized beds with a rotary air distributor driven by the fluidized bed. This further enhances the equipment's airflow control capabilities, ensuring that the material is evenly distributed in the whirlwind-like airflow. The air distributor controls the airflow speed and direction precisely, keeping the material in a suspension state. This not only improves the material's fluidity but also promotes full contact between the material and the airflow, thereby enhancing drying efficiency.

In the granulation process, the role of the air distributor is particularly important. By controlling the distribution of airflow, the equipment can ensure that the material is presented with a regular fluidized state in the drying chamber. Unlike traditional equipment, the fluidized form of XLP series fluidized bed has higher stability and uniformity, overcoming the common problems of trench flow and dead corners in traditional fluidized processes.

3. XLP Series Cyclone Bed Granulation and Drying Machine - Air Distribution Plate - Air Nozzle Spray System

The XLP series of fluidized bed dryers and granulators uses a precision pneumatic nozzle system during the drying and granulation process. The nozzles are installed on the side wall of the drying chamber and spray the binder or coating liquid evenly into the material layer to achieve adhesion and coating. Since the material moves in a regular trajectory under the action of the vortex airflow, the nozzles can ensure that the liquid is evenly covered on the surface of every particle.

The spraying process not only effectively turns the powder into particles, but also ensures that the particle size is uniform and the shape is regular. In particular, for those materials with poor moisture absorption and poor fluidity, the spraying system of the XLP series equipment can also ensure that they can form qualified particles. This flexibility allows the XLP cyclone equipment to achieve good granulation effects when processing materials with different properties.

4. XLP Series Cyclone Bed Granulator and Dryer Air Distribution Plate - Improving Particle Characteristics

The granules produced by the fluidized bed granulation dryer have many excellent properties. Firstly, the fluidized bed technology is adopted, resulting in porous and even granules, which enable better instant dissolution during subsequent processing or use. The porous structure helps the granules to absorb liquid quickly, thus accelerating the dissolution rate. For the pharmaceutical and food industries, instant dissolution is an important indicator for many products, which can significantly enhance the market competitiveness of the products.

The granules produced by the fluidized bed granulation dryer equipment have a high mechanical strength. Although the granules are porous and dissolve quickly, they still have enough strength to withstand breakage during transportation or storage. This increased strength comes from the uniform action of the fluidized gas flow, which makes the structure of the granules more stable during the formation process.

The XLP series of fluidized bed granulation dryers performs excellently when processing hygroscopic and poorly fluid materials. Traditional fluidized bed granulation equipment often has difficulty forming uniform particles when processing such materials, and is prone to clumping or irregular particle formation. Thanks to the unique design of the fluidized bed, the XLP series equipment can effectively avoid these problems, enabling even hygroscopic or poorly fluid materials to be made into high-quality granules.

Jiangsu Bohong Drying Equipment Co., Ltd. produces and manufactures the rotary bed granulation dryer, which ensures the uniform and orderly movement of materials during granulation and drying processes through its special air distribution system, rotary air drive, and precise coating system. This results in the production of high-quality granules that are not only highly porous and instant dissolvable, but also possess a certain level of strength, making them suitable for applications in various industries. In particular, the rotary bed granulation dryer excels in handling materials with high moisture absorption and poor fluidity. Therefore, the rotary bed granulation dryer is a highly competitive equipment that can significantly enhance production processes in various industries.

物料的含水量将直接影响电镀污泥干燥机的干燥效率和产品质量。含水率过高的物料在干燥过程中需要消耗更多的热能,干燥时间也较长,从而降低了设备的生产效率。

江苏博鸿干燥公司针对该物料特性专门设计一级采用空心桨叶干燥机,将物料内的水分从含水40%将至5%,然后直接由出料口将物料进入齿盘式高效粉碎机粉碎。

在污泥干化机中,滤板设置在污泥进料管的底部,当污泥通过污泥进料管时,污泥中的水在重力的作用下流入水池,减少了污泥中的水分,从而初步排水,节约了能源。

截屏,识别二维码

官网:

(点击复制官网简称)

截屏,识别二维码

微信公众号二维码:

(点击复制官网简称)

截屏,识别二维码

抖音企业号二维码:

(点击复制官网简称)

截屏,识别二维码

抖音喷雾产品号二维码:

(点击复制官网简称)