所属分类:流化床干燥

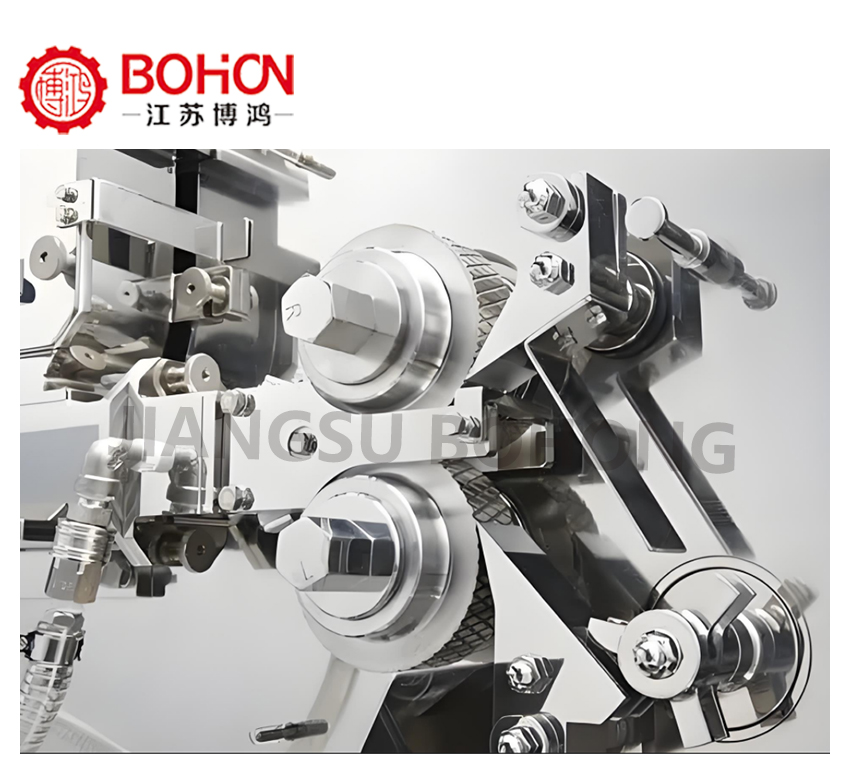

产品简介:The Dry Granulator is mainly used to convert powdered materials into pellets by compression or other mechanical means, without the use of a liquid binder. Dry granulation is usually suitable for pharmaceutical, chemical, food and other industries, especially when dealing with heat sensitive materials is very useful, because it avoids high temperature and moisture.

18651002062

18651002062 The Dry Granulator is mainly used to convert powdered materials into pellets by compression or other mechanical means, without the use of a liquid binder. Dry granulation is usually suitable for pharmaceutical, chemical, food and other industries, especially when dealing with heat sensitive materials is very useful, because it avoids high temperature and moisture.

1. LGX series dry granulator - working principle

The working principle of the dust-free dry granulator includes the following steps:

1.1. ** Feed ** :

- The powdered material enters the granulator through the feed system.

1.2. ** Compression or extrusion ** :

- ** Roller compaction ** : The raw material is compressed into a sheet by the pressure between two high-speed rotating rollers. These flakes are broken into particles by cutting tools.

- ** Extrusion granulation ** : The material is heated and pressured out to form particles through the mold, and then cooled and cut.

1.3. ** Particle forming ** :

- The design of the granulator allows for precise control of the size and shape of the particles.

1.4. ** Dust-free treatment ** :

- The entire process takes place in a sealed environment where dust is effectively contained inside the equipment, usually collected through a dust recovery system.

1.5. ** Discharge ** :

- After the completion of pelleting, the particles are discharged through the discharge system, and the sealing design of the equipment ensures that no dust leakage occurs during the discharge process.

2. LGX series dry granulator - equipment advantages

2.1. ** Dust Control ** :

- With a fully sealed design and dust recovery system, dust pollution can be effectively reduced to provide a clean operating environment.

2.2. ** Improve product quality ** :

- Reduce dust and pollution and help improve the quality and consistency of the final product.

2.3. ** Security **

- Protect operators from dust and harmful substances and improve the safety of the production environment.

2.4. ** Cost savings ** :

- Reduced waste caused by dust and environmental cleaning costs, dust recovery system can be recycled.

2.5. ** Easy to clean ** :

- ** Features ** : The equipment is designed with easy cleaning in mind and can usually be quickly disassembled and cleaned, reducing the risk of cross-contamination.

2.6. ** Sealing design ** :

- ** Function ** : The equipment adopts a fully sealed design to prevent dust from leaking into the external environment and protect the health of the operator.

- ** Application ** : Often used to handle drugs, food or other dust-sensitive materials.

2.7. ** Dust Recovery System ** :

- ** Function ** : Equipped with dust recovery system, the generated dust will be collected again, reduce waste and environmental pollution.

- ** Application ** : effectively improve production efficiency, reduce cleaning and maintenance costs.

2.8. The most efficient granulation effect ** :

- ** Working principle ** : The powder is pressed into particles by high-pressure roller pressing, cutting, etc. The size and shape of the particles can be controlled by adjusting the equipment parameters.

- ** Application ** : To ensure the uniformity and quality of the particles.

2.9. ** Automatic Control ** :

- ** Function ** : Usually equipped with advanced PLC control system to achieve automatic operation and improve production efficiency.

- ** Application: easy to operate and monitor, improve the stability and consistency of the production process.

3. LGX series dry granulator - dust-free conveying

- ** Conveying system ** : The dust-free dry granulator is equipped with a special dust-free conveying system, including sealed conveying pipes and dust collection devices. In the conveying process, negative pressure or positive pressure is used to transport materials to the inside of the granulator to avoid dust leakage.

- ** Dust collection device ** : Usually includes efficient dust collection device, such as bag filter or cyclone separator, can effectively capture and recover dust.

4. LGX series dry granulator - equipment maintenance

4.1. ** Regular cleaning ** :

- Clean equipment regularly to ensure a dust-free environment and reduce the risk of cross-contamination.

4.2. ** Check and replace parts ** :

- Regularly check the wear of key components such as rolls, cutting tools, etc., and replace the worn parts in time.

4.3. ** Lubrication ** :

- Check and add lubricant regularly to ensure smooth operation of equipment and reduce failure.

4.4. ** System Calibration ** :

- Regular calibration of the automation control system to ensure accurate operation of the equipment.

4.5. ** Safety Check ** :

- Check the tightness and safety devices of the equipment to ensure that the safety requirements are met.

5. LGX series dry granulator - scope of use

5.1. ** Pharmaceutical Industry ** :

- The production of pharmaceutical particles, such as tablets, capsule fillers, etc., requires high dust control.

5.2. ** Food Industry ** :

- Suitable for the production of food additives, nutritional supplements, etc., to ensure the safety and quality of food.

5.3. ** Chemical Industry ** :

- Handling chemical raw materials and products, such as plastics, dyes, etc., with strict requirements for dust and pollution.

5.4. ** Materials Science ** :

- For the production of advanced materials, such as high-performance ceramics, alloy materials, etc., to ensure the uniformity and purity of materials.

The dust-free dense drying granulator manufactured by Jiangsu Bohong is an efficient and environmentally friendly equipment, which is suitable for industries with high requirements for production environment and product quality.

物料的含水量将直接影响电镀污泥干燥机的干燥效率和产品质量。含水率过高的物料在干燥过程中需要消耗更多的热能,干燥时间也较长,从而降低了设备的生产效率。

江苏博鸿干燥公司针对该物料特性专门设计一级采用空心桨叶干燥机,将物料内的水分从含水40%将至5%,然后直接由出料口将物料进入齿盘式高效粉碎机粉碎。

在污泥干化机中,滤板设置在污泥进料管的底部,当污泥通过污泥进料管时,污泥中的水在重力的作用下流入水池,减少了污泥中的水分,从而初步排水,节约了能源。

截屏,识别二维码

官网:

(点击复制官网简称)

截屏,识别二维码

微信公众号二维码:

(点击复制官网简称)

截屏,识别二维码

抖音企业号二维码:

(点击复制官网简称)

截屏,识别二维码

抖音喷雾产品号二维码:

(点击复制官网简称)