所属分类:流化床干燥

产品简介:FPCG 系列多功能流化床是专为制药、食品和化工行业设计的集多种功能于一体的先进制粒设备。它可以进行混合、干燥、制粒、包衣和微胶囊形成等多种操作,是现代生产工艺中不可或缺的设备。

18651002062

18651002062 FPCG Series Multifunctional Fluidized Bed

The FPCG Series Multi-Function Fluidized Bed is an advanced granulation equipment that integrates multiple functions, specially designed for the pharmaceutical, food, and chemical industries. It can perform a variety of operations, including mixing, drying, granulation, coating, and microcapsule formation, making it an indispensable piece of equipment in modern production processes. Due to the fluidized bed's high flexibility and efficient production performance, the equipment can be adjusted to meet different production needs, making it an ideal choice for improving production efficiency and optimizing production processes.

Ⅰ FPCG Series Multi-Function Fluidized Bed - Equipment Application

The FPCG series multi-function fluidized bed is widely used in various industries due to its rich functional combination. It plays an especially important role in the pharmaceutical industry, where it can meet the preparation needs of different types of drugs. The equipment can efficiently complete granulation, drying, and coating processes by integrating top spray, bottom spray, and side spray functions. Besides, the food industry can use the equipment to prepare food particles and coat them, while the chemical industry can use it to modify and process particles.

1. **Granulation**: Using the top spray function, the equipment can convert powdered materials into uniform granules, suitable for pharmaceutical granulation or food granule production.

2. **Drying**: Utilizing airflow technology, the equipment can dry materials quickly and efficiently, suitable for dehydration treatment of various materials.

3. **Coating**: The bottom and side spray functions allow for coating operations on granules or microspheres to improve drug release performance or protect the material.

4. **Microsphere preparation**: Using the side spray function, the equipment can prepare microspheres, widely used in the production of drug sustained-release and controlled-release formulations.

The integrated design of the multi-function fluidized bed makes the FPCG series multi-function fluidized bed highly adaptable and advantageous in a variety of fields, including pharmaceuticals, food, and chemicals.

Ⅱ The FPCG Series Multi-Function Fluidized Bed - Working Principle

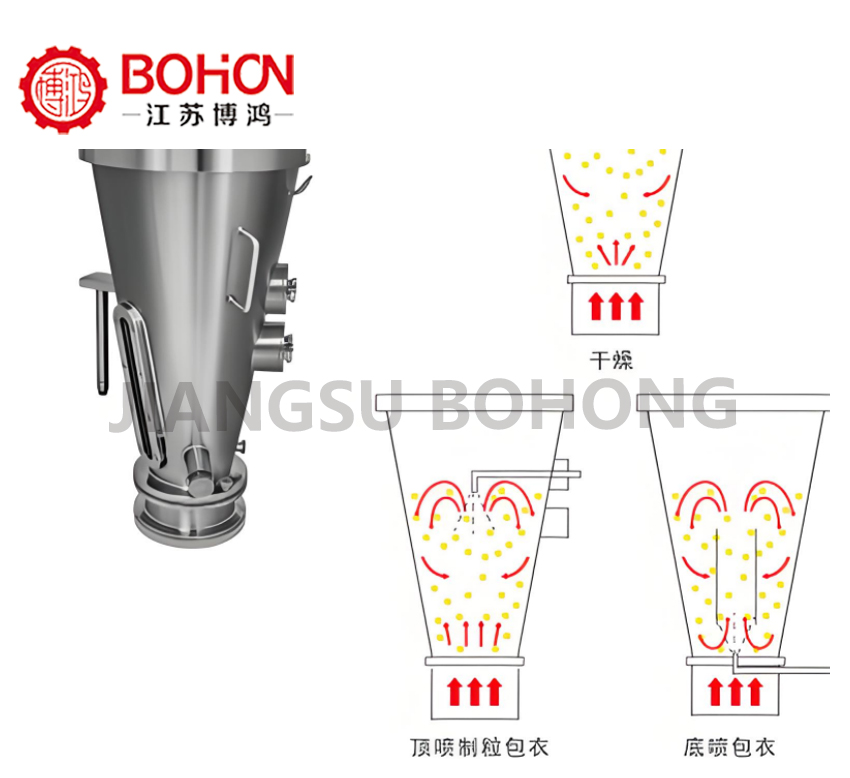

The FPCG series multi-function fluidized bed is mainly composed of the inlet air system, fluidized bed system, top spray system, bottom spray system, side spray system, and outlet air system. Each system works together to ensure that the material can be uniformly and quickly processed during the fluidization process according to the required operation.

- **Top Spray System**: This system is mainly used for granulation function. The material is introduced into the fluidized bed through the air inlet system, and the airflow lifts the material and suspends it in the air. Then, the liquid spray is sprayed onto the material through the top spray head, forming granules. This process can effectively control the size and shape of the granules, ensuring a uniform and consistent quality of the granules produced.

- **Bottom Spray System**: used for microcapsule coating function. The bottom spray system uses special designed nozzles to evenly spray the coating liquid onto suspended microcapsules. Airflow causes the microcapsules to continuously roll and receive the spray, thus forming a uniform coating layer.

- **Side-spray system**: This system is mainly used for preparing microspheres. The material is sprayed through the side-spray system, and the airflow carries the material to move, while forming microspheres at the same time. This system is suitable for handling smaller particle materials, such as drug-controlled release microspheres.

Each functional module can be used independently according to production needs, or multiple modules can be combined to achieve continuous or alternating operation of drying, granulation, and coating processes. Users can choose different functional configurations based on their actual production process requirements, thus maximizing the utilization rate and production efficiency of the equipment.

Ⅲ FPCG Series Multi-Function Fluidized Bed - Equipment Features

The FPCG series multi-function fluidized bed boiler features numerous innovative designs and technical features, making it competitive in the market:

1. **Modular design**: The multi-function fluidized bed equipment is designed with modular components, allowing for flexible configuration of top, bottom, and side spray functions. Customers can choose the appropriate functional modules based on their production needs. This flexibility enables the equipment to adapt to different production tasks and quickly switch between functions.

2. **Multifunctional Integration**: The device integrates the functions of drying, granulation, coating, and microcapsule preparation into one machine, allowing users to easily perform multiple operations with different process settings, reducing the switching time and space requirements during production.

3. **PLC Full Automatic Control**: The multi-function fluidized bed is equipped with an advanced PLC full automatic control system. By setting process parameters, the equipment can automatically complete the entire production process operation, greatly reducing the need for manual intervention. The full automatic control system can also monitor and record key process parameters in real-time, ensuring the stability and reproducibility of the production process.

4. **Compliance with GMP requirements**: The design and manufacture of the multi-function fluidized bed fully comply with GMP (Good Manufacturing Practices for Pharmaceutical Products) standards, ensuring the safety and reliability of the equipment in pharmaceutical production. At the same time, all process records and parameters can be printed and archived through the system, ensuring the authenticity and traceability of production data.

5. **Highly efficient mixing and drying capabilities**: The multi-function fluidized bed utilizes air suspension technology to uniformly mix and dry materials in a short period of time, significantly improving production efficiency and ensuring the stability of product quality.

Ⅳ FPCG Series Multi-Function Fluidized Bed - Application Fields

The FPCG series multi-function fluidized bed has a wide range of applications, especially in the pharmaceutical, food, and chemical industries, where it has received high recognition. Here are its main application scenarios:

- **Pharmaceutical Industry**: Can be used to prepare granules or microspheres for tablets and capsules, and can also perform coating operations on drugs. In particular, the coating operation of microspheres is crucial in sustained and controlled release formulations, and the equipment can achieve uniform and precise coating effects through its bottom spray and side spray systems.

- **Food Industry**: used for the preparation and coating treatment of food particles, such as the production of seasonings, food additives, etc. The versatility of the equipment makes it easy to adapt to different food recipe requirements.

- **Chemical Industry**: Particle preparation, modification, and coating treatment in chemical production, equipment for processing and modifying materials of different types, optimizing product performance.

The FPCG series multi-function fluidized bed, with its advanced design, flexible function configuration, and outstanding automation control, has become an indispensable important equipment in modern industrial production. It not only improves production efficiency but also provides reliable solutions for the preparation and processing of various materials. Through modular design and full automation, the equipment can easily meet the diverse needs of different production fields and fully comply with GMP standards, making it an ideal choice for the pharmaceutical, food, and chemical industries.

物料的含水量将直接影响电镀污泥干燥机的干燥效率和产品质量。含水率过高的物料在干燥过程中需要消耗更多的热能,干燥时间也较长,从而降低了设备的生产效率。

江苏博鸿干燥公司针对该物料特性专门设计一级采用空心桨叶干燥机,将物料内的水分从含水40%将至5%,然后直接由出料口将物料进入齿盘式高效粉碎机粉碎。

在污泥干化机中,滤板设置在污泥进料管的底部,当污泥通过污泥进料管时,污泥中的水在重力的作用下流入水池,减少了污泥中的水分,从而初步排水,节约了能源。

截屏,识别二维码

官网:

(点击复制官网简称)

截屏,识别二维码

微信公众号二维码:

(点击复制官网简称)

截屏,识别二维码

抖音企业号二维码:

(点击复制官网简称)

截屏,识别二维码

抖音喷雾产品号二维码:

(点击复制官网简称)