所属分类:流化床干燥

产品简介:The FPCG Series Fluidized Bed Granulation and Coating Machine is an advanced equipment independently designed and manufactured by Jiangsu Bohong, specifically developed for granulation and coating processes in the pharmaceutical and chemical industries.

18651002062

18651002062 FPCG Series Fluidized Bed Granulation and Coating Machine - Equipment Overview

1. FPCG Series Fluidized Bed Pelletizing and Coating Machine--Equipment Overview

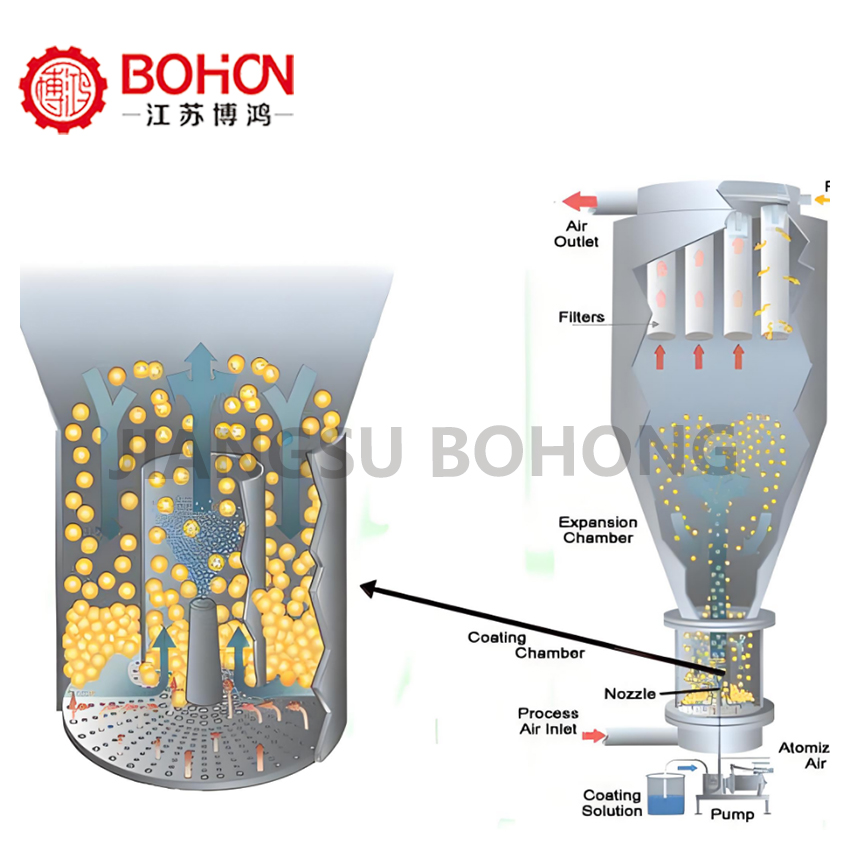

The FPCG Series Fluidized Bed Granulation and Coating Machine is an advanced equipment independently designed and manufactured by Jiangsu Bohong, specifically developed for granulation and coating processes in the pharmaceutical and chemical industries. The equipment strictly follows the company's proprietary standards in design and combines leading global manufacturing levels to ensure that key performance indicators such as reproducibility, uniformity, and homogeneity are achieved or even surpass international leading levels. Its flexible design and diverse functions allow for quick switching between different formulations and production environments, meeting the production needs of different customers to a great extent.

2. FPCG Series Fluidized Bed Granulation and Coating Machine - Equipment Design Features

2.1 Aerodynamic Design

The FPCG series fluidized bed granulation coating machine adopts a unique aerodynamic design to ensure uniformity of the airflow structure. This design not only ensures a uniform distribution of gas throughout the entire system, but also provides each particle with consistent heating and cooling effects through optimized airflow paths.

2.2 Precise Process Control

The fluidized bed granulation and coating equipment is equipped with precise temperature and humidity control capabilities, which can monitor and adjust key process parameters in real-time to ensure stability of the process conditions. This control system can dynamically adjust various parameters based on the properties of the material, ensuring reproducibility and uniformity of the production.

2.3 Anti-static Filter Bags for Inhalation

The fluidized bed granulation coating equipment is equipped with anti-static filter bags, which have excellent air permeability and can effectively prevent safety problems caused by static charge accumulation during production. At the same time, the use of imported spray guns also improves the atomization effect, allowing the coating material to be evenly distributed on the particle surface, ensuring the stability of the coating product quality.

3. FPCG Series Fluidized Bed Granulation and Coating Machine - Equipment Advantages

The fluidized bed granulation and coating equipment has many technical advantages, making it highly competitive in both domestic and international markets. Its multi-functional design allows the equipment to be flexibly applied to different production processes and meet the needs of different industries. The main advantages are as follows:

3.1 Excellent Uniformity and Reproducibility

Through optimized airflow design and precise process control, the equipment can ensure the uniformity of granulation and coating products. In addition, the fluidized bed granulation coating equipment has good parallel scaling, i.e., it can maintain consistent product quality in different scale production.

3.2 Reduce raw materials and auxiliary materials

In some production processes, the fluidized bed granulation and coating equipment can reduce the use of raw materials and auxiliary materials by customizing its functions according to the different properties of the materials, thus lowering production costs.

3.3 High Automation Level

The fluidized bed granulation and coating equipment has a high level of automation, which can easily be integrated with other granulation equipment to meet customers' requirements for automated production. This not only improves production efficiency but also reduces the impact of human intervention on the production process.

4. FPCG Series Fluidized Bed Granulation and Coating Machine - Application Fields

The versatility of fluid bed granulation and coating equipment makes it suitable for a wide range of pharmaceutical and chemical applications. The equipment can be customized according to the properties of different materials and process requirements, and its main areas of application include:

1. **Tablets**: By using efficient granulation and coating processes, we ensure the uniformity and dissolution of tablets.

2. **Capsules**: We improve the uniformity of the particles within capsules to ensure that the active ingredients in each capsule are distributed evenly.

3. **Granules**: We ensure the fluidity and consistency of appearance for granule products after coating.

4. **Fine Powder**: Used for the preparation of fine powder in traditional Chinese medicine and Western medicine, to ensure the stability of the drug effect.

5. **Microsphere Coating**: High-quality coating for microspheres to improve the drug's sustained release effect.

6. **Powder Coating**: Powders can be evenly coated to improve their stability and solubility.

The FPCG series fluidized bed granulation coating machine, with its unique design, high degree of automation, and flexible application, has become an ideal choice for the pharmaceutical and chemical industries. Its outstanding process control capabilities, energy-saving design, and flexible and diverse application scenarios make it have great market potential in the future industry development.

物料的含水量将直接影响电镀污泥干燥机的干燥效率和产品质量。含水率过高的物料在干燥过程中需要消耗更多的热能,干燥时间也较长,从而降低了设备的生产效率。

江苏博鸿干燥公司针对该物料特性专门设计一级采用空心桨叶干燥机,将物料内的水分从含水40%将至5%,然后直接由出料口将物料进入齿盘式高效粉碎机粉碎。

在污泥干化机中,滤板设置在污泥进料管的底部,当污泥通过污泥进料管时,污泥中的水在重力的作用下流入水池,减少了污泥中的水分,从而初步排水,节约了能源。

截屏,识别二维码

官网:

(点击复制官网简称)

截屏,识别二维码

微信公众号二维码:

(点击复制官网简称)

截屏,识别二维码

抖音企业号二维码:

(点击复制官网简称)

截屏,识别二维码

抖音喷雾产品号二维码:

(点击复制官网简称)