所属分类:流化床干燥

产品简介:XF series horizontal fluidized bed boiling dryer, or fluidized bed dryer, its core working principle is based on the heat and mass exchange of solid materials in the fluidized state. The granular solid material enters the fluidized-bed machine through the feeder.

18651002062

18651002062 XF Series Horizontal Fluidized Bed boiling dryer (fluidized bed dryer)

1. XF series horizontal fluidized bed boiling dryer - working principle

XF series horizontal fluidized bed boiling dryer, or fluidized bed dryer, its core working principle is based on the heat and mass exchange of solid materials in the fluidized state. The granular solid material enters the fluidized-bed machine through the feeder.

At the same time, the filtered clean air is heated to the required temperature by the heater and sent to the bottom of the fluidized bed by the blower. This hot air is evenly dispersed through the distribution plate, contacting the solid material and forming a fluidization (similar to boiling state), thus achieving efficient gas-solid heat and mass exchange. The material dries quickly in the fluidization process and is then discharged through the discharge port.

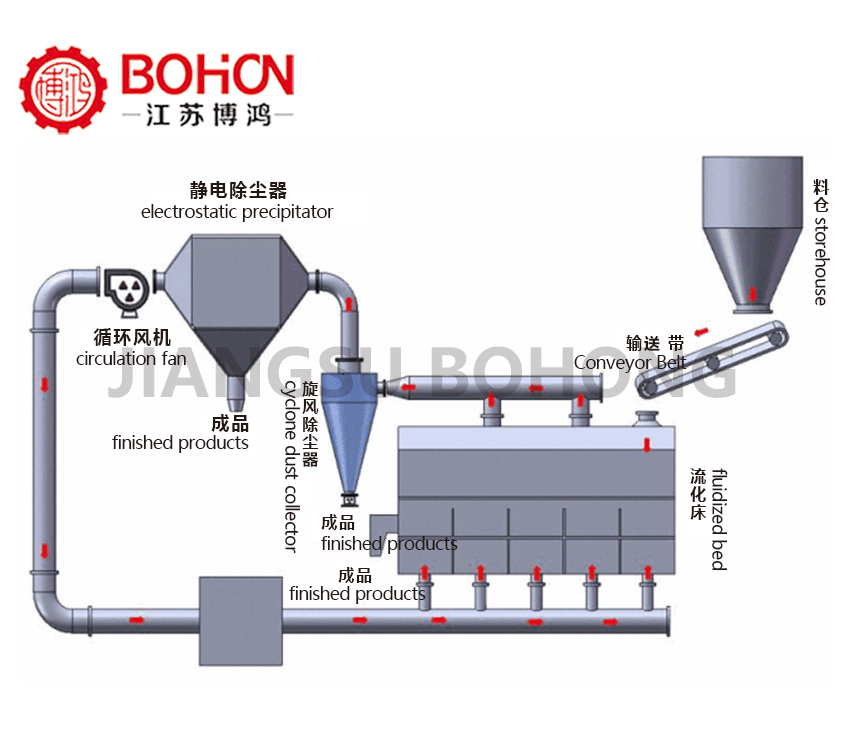

The waste gas produced in the horizontal fluidized bed boiling drying process carries a small amount of fine powder, which is discharged through the top of the boiling bed, and is recovered by the cyclone dust collector and the cloth bag dust collector successively, and finally the clean waste gas is emptied.

2. XF series horizontal fluidized bed boiling dryer - equipment introduction

XF series horizontal fluidized bed boiling dryer is a kind of high efficiency solid material drying equipment, mainly composed of air filter, heater, boiling bed host, feeder, cyclone separator, bag dust collector, high pressure centrifugal fan and operation table and other components.

According to the different properties of the drying materials, different combinations of dust removal equipment can be selected to optimize the dust recovery effect. For large proportion of materials such as powder and granular materials, usually only need to be equipped with a cyclone separator to meet the needs; For small granular and powdery materials with light gravity, it is necessary to be equipped with a bag dust collector to ensure efficient dust removal.

In addition, the horizontal fluidized bed boiling dryer equipment manufactured by Jiangsu Bohong Drying production can also be equipped with pneumatic feeding devices to further improve production efficiency and automation level.

3. XF series horizontal fluidized bed boiling dryer - application range

XF series horizontal fluidized bed boiling dryer is widely used in the drying field of bulk granular materials, including but not limited to the following aspects:

1. Pharmaceutical products ** : raw materials, tablet granules, Chinese medicine granules, etc.

2. ** Chemical raw materials ** : plastic resin, citric acid and other powdery, granular materials.

3. ** Food and food processing ** : food and beverage granules, corn germ, feed, etc.

The horizontal fluidized bed boiling drying equipment is especially suitable for processing materials with particle size in the range of 0.1 ~ 6mm, of which the optimal particle size range is 0.5 ~ 3mm. By adjusting the operating parameters such as hot air temperature, flow rate and the amount of material added, the drying process can be precisely controlled to ensure that the material can achieve the ideal drying effect.

4. XF series horizontal fluidized bed boiling dryer - heat source selection

The heat source of the XF series horizontal fluidized bed boiling dryer can be flexibly configured according to customer requirements, including steam, electric heating and hot blast stove. Each heat source has its own advantages, which can be comprehensively considered and selected according to the actual production conditions, energy consumption requirements and environmental protection policies.

物料的含水量将直接影响电镀污泥干燥机的干燥效率和产品质量。含水率过高的物料在干燥过程中需要消耗更多的热能,干燥时间也较长,从而降低了设备的生产效率。

江苏博鸿干燥公司针对该物料特性专门设计一级采用空心桨叶干燥机,将物料内的水分从含水40%将至5%,然后直接由出料口将物料进入齿盘式高效粉碎机粉碎。

在污泥干化机中,滤板设置在污泥进料管的底部,当污泥通过污泥进料管时,污泥中的水在重力的作用下流入水池,减少了污泥中的水分,从而初步排水,节约了能源。

截屏,识别二维码

官网:

(点击复制官网简称)

截屏,识别二维码

微信公众号二维码:

(点击复制官网简称)

截屏,识别二维码

抖音企业号二维码:

(点击复制官网简称)

截屏,识别二维码

抖音喷雾产品号二维码:

(点击复制官网简称)